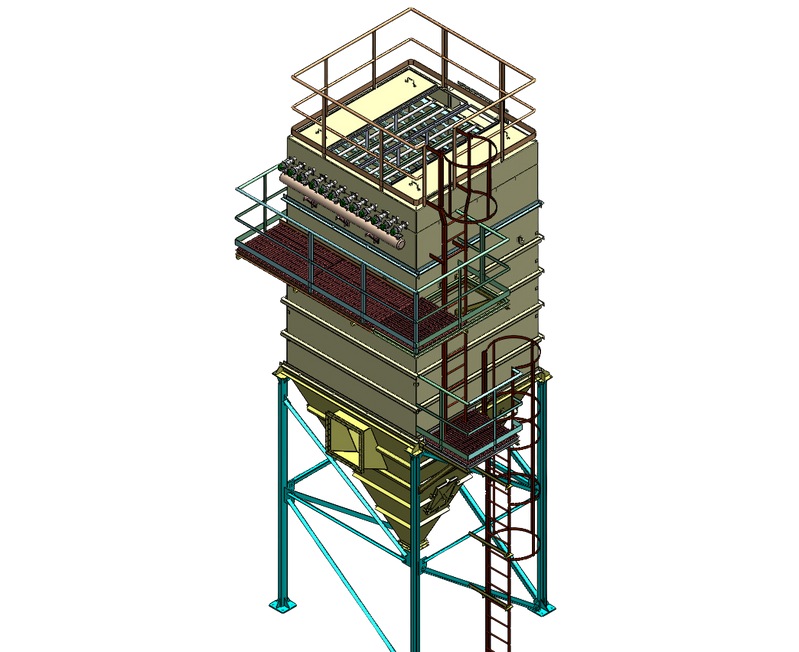

Ionfiltra’s Pulse Jet Bag Filters provide one of the most versatile and effective dust control solutions on the market. Specifically designed to offer superior separation efficiency, these filters are customizable to meet the unique needs of various industrial applications, ensuring both high performance and low emissions.

Longer Bag Life

Structure Compliant with IS 800-2007, AISC 2010

Low Consumption of Compressed Air

Compliance with the latest air pollution norms

Laser Cut Accuracy

Advanced 3D Design

Low Maintainance

Dedicated CFD Setup

Durable Filter Bag Cages

Complete Inhouse Manufacturing

On time Delivery

Customized Solutions

Easy Installation

High Efficiency

For high reliability and lower emissions, Ionfiltra’s Pulse Jet Bag Filter is an ideal solution. Its versatile design ensures excellent separation efficiency, with cleaning achieved through compressed air pulses based on continuous Differential Pressure monitoring using a Sequential Controller.

The Online Pulse Jet Bag Filter is one of the most efficient and widely used options. It includes a Capsule at the top with a Bag Mounting assembly inside the Casing, connected to a dust evacuation system such as a Rotary Airlock Valve.

Operation: Dust-laden gas enters the Hopper, flows through the filter bags, where dust is collected and discharged. Clean gas exits through the top opening.

Ideal for applications with belt conveyor transfer points, bins, hoppers, or silos where dust control is critical.

Design: This flush-mounted filter is attached directly to the venting point, eliminating the need for a hopper, support structure, or additional dust evacuation systems.

Application: Dust is vented directly into the Silo, Hopper, Bin, or onto the conveyor belt below, ensuring efficient dust control at transfer points.

Bag Filters with capacities up to 20,000 m³/hr are widely used in various industries due to their high-efficiency filtration systems, which ensure effective dust control and air quality management. The most common dust entry method is through a single hopper entry, where dust-laden air is directed into the hopper and evenly distributed across the filter bags, maximizing filtration efficiency. This straightforward entry design simplifies maintenance and ensures consistent dust collection, making it a preferred choice in industrial applications.

Simultaneous hopper entry can be achieved by directing dust-laden air into two hoppers using a Y-joint at the inlet, allowing for balanced distribution across multiple sections of the Bag Filter. Inlet velocities are maintained at approximately 10 m/s to optimize filtration performance, ensuring efficient dust capture while minimizing wear on the filter components. This design enhances the overall effectiveness and longevity of the Bag Filter, making it suitable for high-demand industrial applications.

For Bag Filters handling high dust loads, hopper entry is typically avoided; instead, a casing entry with a specially designed inlet plenum is used. This configuration allows the dust-laden air to enter directly into the filter casing, where the inlet plenum evenly distributes the air across the filter bags. This design prevents excessive dust accumulation in the hopper, enhances filtration efficiency, and reduces wear, making it ideal for applications with high dust concentrations.

Bag filters designed for high dust loads are typically not provided with a direct hopper entry. Instead, a casing entry is utilized, which is equipped with a specially designed inlet plenum. This design ensures that the dust-laden air enters the bag filter system in a controlled manner, reducing turbulence and allowing for better distribution of the incoming air across the filtration area. The inlet plenum helps to maintain the efficiency of the filtration process, preventing issues such as uneven dust loading on the filter bags, and minimizes the risk of clogging or damage to the bags.

Ionfiltra offers a comprehensive range of filter bags to meet your specific filtration requirements, including pulse-jet, plenum pulse, shaker bags, and envelope filter bags. All designs are engineered for high-temperature and static dissipation applications. We provide filter bags in a variety of fiber types, ensuring optimal performance across different filtration technologies.

Ionfiltra’s pleated filter bags, with integrated cages, offer a direct replacement for traditional bags and cages in numerous applications. These pleated bags provide enhanced filtration efficiency and a reduced footprint, making installation easier and more efficient.

Dust Load plays an important load in the performance of a Bag Filter. Higher dust loads means higher loading of dust on the bags.

If the entry of dust is not handle properly, it may lead to higher deposition of dust on the bags thus rising differential pressure & in turn leading to blinding of bags.

Thus Ionfiltra provides customized solutions for GAS DISTRIBUTION in a Bag Filter.

| Operating Variables | Polypropylene | Polyester | Acrylic | Fibre Glass | Polyaramide | Co-Polyimide | PTFE |

| Max Operating Temp° C | 76 | 134 | 140 | 259 | 190 | 259 | 259 |

| Abrasion | Excellent | Excellent | Good | Fair | Excellent | Fair | Good |

| Filtration Properties | Good | Excellent | Good | Fair | Excellent | Excellent | Fair |

| Moist Heat Hydrolysis | Excellent | Poor | Excellent | Excellent | Good | Good | Excellent |

| Alkali | Excellent | Fair | Fair | Fair | Good | Fair | Excellent |

| Acids | Excellent | Fair | Good | Poor | Fair | Good | Excellent |

| Relative Cost | X | XX | XXX | XXXX | XXXXX | XXXXXX | XXXXXX |

We offer bespoke solutions tailored to your specific needs, whether for extreme temperatures, corrosive environments, or high-pressure systems. Our Products can be customized with various sealing arrangements, actuation methods, and materials to meet your application’s unique requirements.