- About us

- Products & Solutions

Air Pollution Control Products

Solid Handling Products

Air Handling Products

- Careers

- Services

- About us

- Products & Solutions

Air Pollution Control Products

Solid Handling Products

Air Handling Products

- Careers

- Services

If your Electrostatic Precipitator (ESP) is underperforming, consider these upgrades to enhance efficiency, reliability, and compliance.

Enhance ESP performance to address:

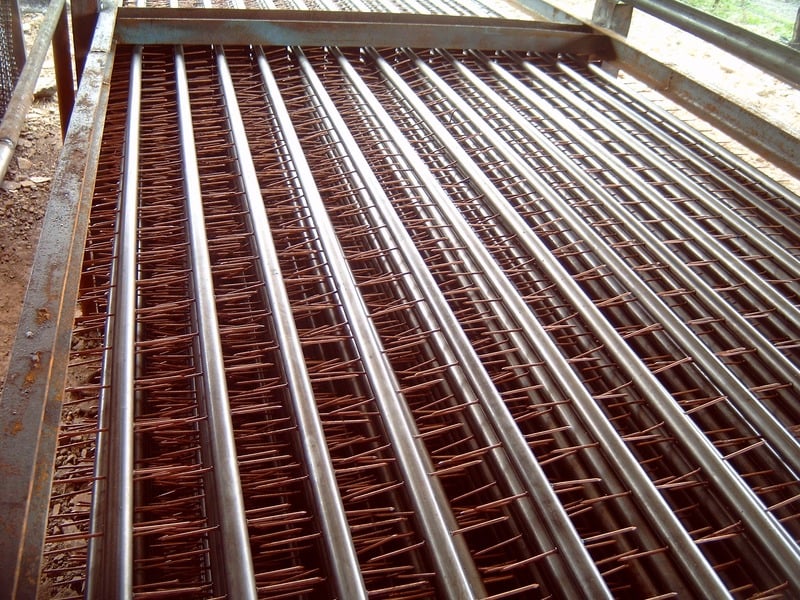

Upgrade to Ionfiltra’s latest Pipe & Spike Emitting Electrodes for robust, high-performance operation.

Features:

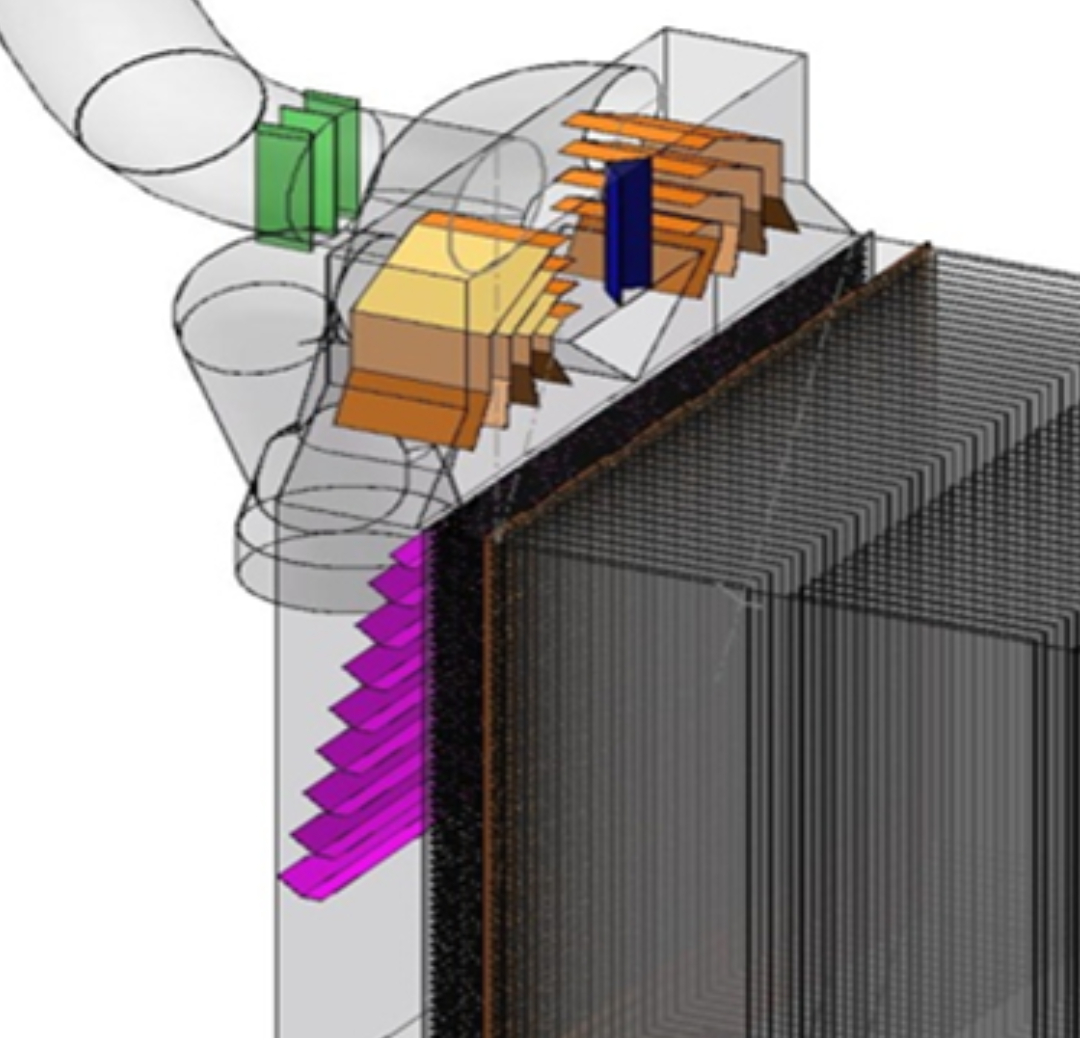

Ionfiltra’s new Spiral Electrodes are designed for enhanced performance in ESPs.

Key Features:

Technical Specifications:

The VT963 Voltage Transmitter is engineered for precise monitoring of medium and high voltage distribution systems and demanding environments like Electrostatic Precipitators (ESP). With its ability to handle DC voltages up to 100kV, the VT963 delivers reliable measurements, utilizing a 0-20 milliamp proportional current output. Unlike standard voltage dividers, it boasts near-infinite input impedance, maintaining high charge levels in ESPs for optimal performance and minimizing back corona effects.

Our specialized ESP Insulators are engineered to excel in harsh electrostatic precipitator environments, ensuring superior performance and durability. Designed to withstand challenging conditions, they offer:

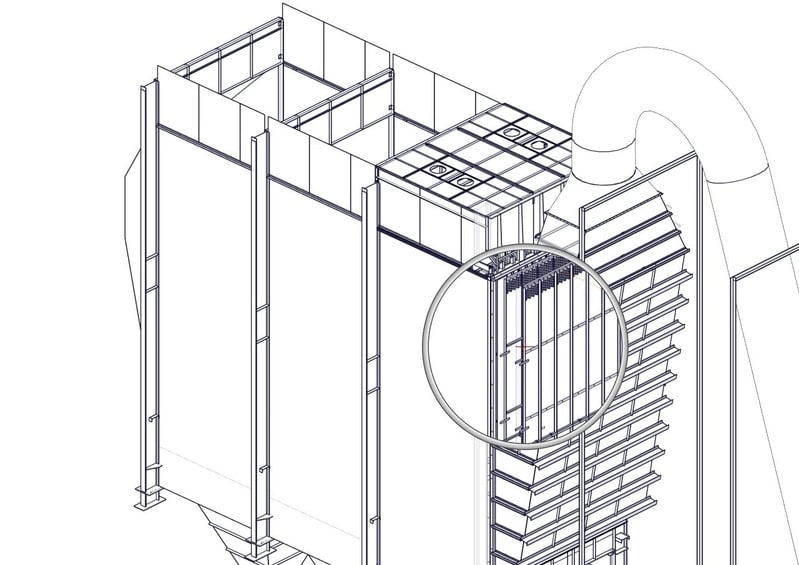

Ionfiltra provides design and installation of Turning Vanes (Gas Distribution Vanes) in the ESP’s inlet duct.

Benefits:

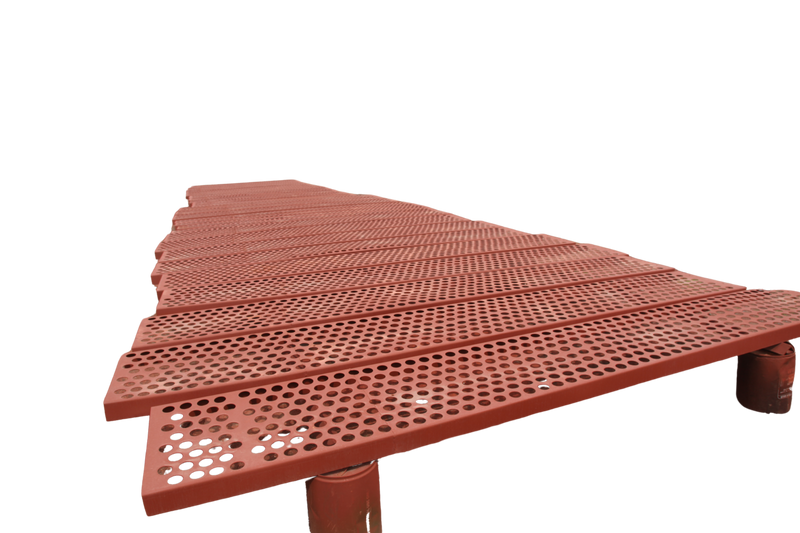

Optimize your ESP with Ionfiltra’s custom-designed Gas Distribution Screens.

Advantages:

We offer bespoke solutions tailored to your specific needs, whether for extreme temperatures, corrosive environments, or high-pressure systems. Our Products can be customized with various sealing arrangements, actuation methods, and materials to meet your application’s unique requirements.

Established in 2001, Ionfiltra rapidly gained prominence in the energy and environmental sectors, focusing on air pollution control. With 20 years of experience, Ionfiltra regulates solid and gaseous discharges, partnering with tech firms for comprehensive solutions. Their equipment selection balances Capital and Operational Expenditure for optimal results.