- About us

- Products & Solutions

Air Pollution Control Products

Solid Handling Products

Air Handling Products

- Careers

- Services

- About us

- Products & Solutions

Air Pollution Control Products

Solid Handling Products

Air Handling Products

- Careers

- Services

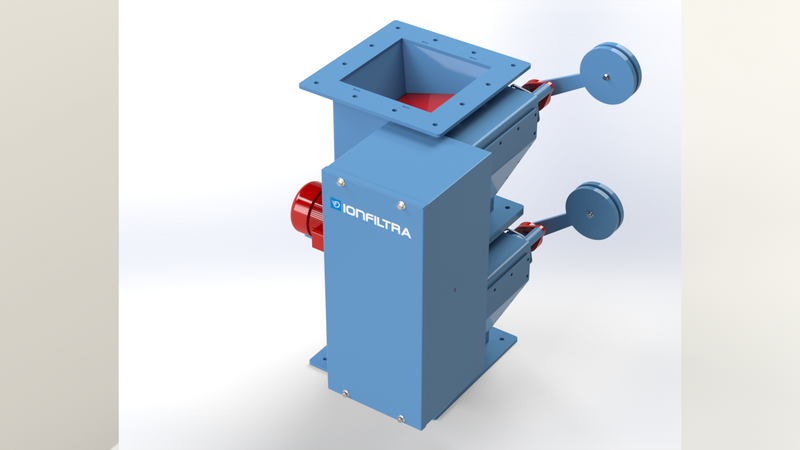

Ionfiltra’s Double Flap Valve (DFV) is a robust solution for managing free-flowing, abrasive materials in high-temperature environments. These valves are specifically designed for discharging bulk materials from hoppers and silos while maintaining an airlock. Their rugged construction makes them ideal for handling heavy-duty industrial applications.

Available from 250 mm to 500 mm

Up to 900°C

Capable of operating under negative pressures up to 0.1 bar

Can handle between 8 and 48 liters per cycle

The DFV is used for airlock discharge in high-temperature, abrasive material systems like those found in cement, mining, and metallurgical industries. It is also ideal for handling large particle size and heavy-duty applications.

We offer bespoke solutions tailored to your specific needs, whether for extreme temperatures, corrosive environments, or high-pressure systems. Our products can be customized with various sealing arrangements, actuation methods, and materials to meet your application’s unique requirements.

Established in 2001, Ionfiltra rapidly gained prominence in the energy and environmental sectors, focusing on air pollution control. With 20 years of experience, Ionfiltra regulates solid and gaseous discharges, partnering with tech firms for comprehensive solutions. Their equipment selection balances Capital and Operational Expenditure for optimal results.