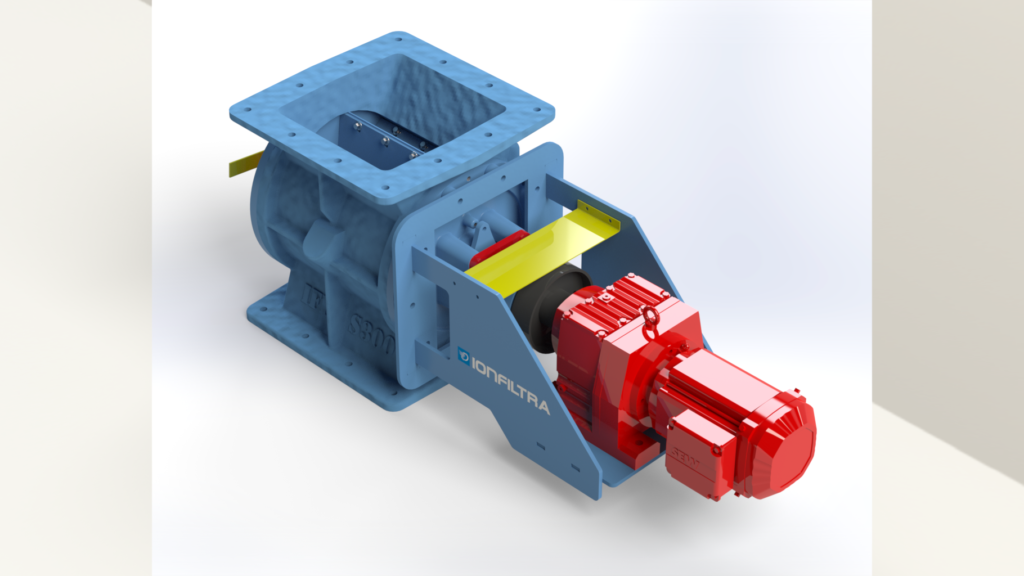

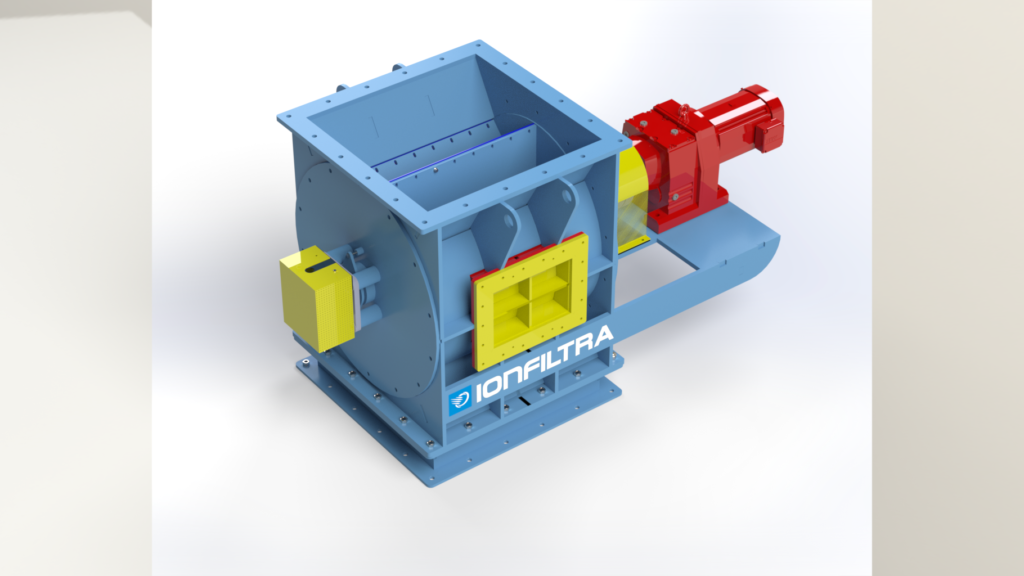

Ionfiltra’s Rotary Airlock Valves (RAV) are engineered for demanding industrial applications where precise control of material flow is essential. These valves act as airlocks while transferring materials from one system to another, ensuring minimal air leakage. The valves are designed to withstand abrasive materials, high temperatures, and harsh environments, making them ideal for dust collection systems, cyclones, and metering applications.

Up to 1000mmx1000mm

Up to 350°C

Constructed from cast iron, carbon steel, or stainless steel

Available in hardened steel, stainless steel, or Vulkollan, providing excellent wear resistance.

The RAV is designed to handle airlocks for dust collectors, cyclones, and material metering systems in industries such as cement, minerals, and food processing. The rugged design ensures consistent operation even with abrasive or high-temperature materials.

We offer bespoke solutions tailored to your specific needs, whether for extreme temperatures, corrosive environments, or high-pressure systems. Our products can be customized with various sealing arrangements, actuation methods, and materials to meet your application’s unique requirements.