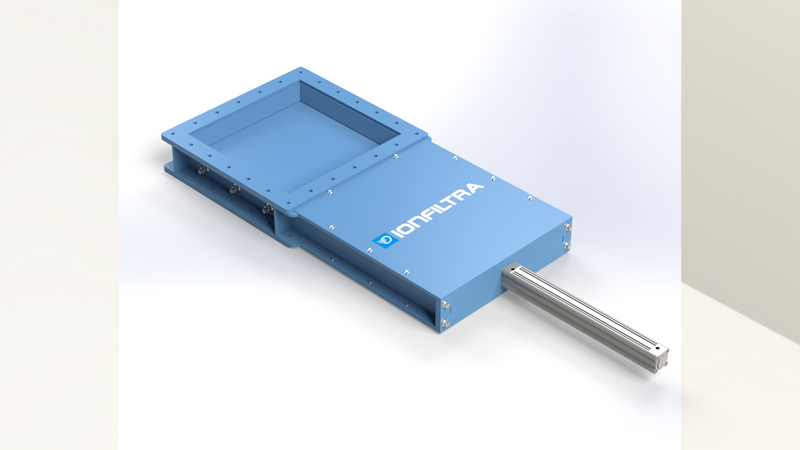

Ionfiltra’s Slide Gate is an industry-leading solution for regulating material flow in gravity-fed and low-pressure systems. Whether installed under hoppers, silos, or mixers, this gate excels in managing bulk materials with precision and durability. Its compact and flexible design ensures efficient operation in a variety of space-constrained environments.

Up to 1000x1000mm

Up to 1000°C

Available in Mild Steel, stainless steel, offering excellent strength and corrosion resistance.

Bonnet seals that can be replaced while the valve remains in-line, minimizing downtime and maintenance efforts.

The Slide Gate is perfect for use in gravity-fed applications, including under hoppers, silos, and mixers. It also functions as an efficient air shut-off gate in vacuum dust collection systems, providing reliable control over material flow.

We offer bespoke solutions tailored to your specific needs, whether for extreme temperatures, corrosive environments, or high-pressure systems. Our products can be customized with various sealing arrangements, actuation methods, and materials to meet your application’s unique requirements.